As an integrated garment manufacturing business, we recognize the tremendous environmental footprint of the garment industry as a whole and have taken active steps to positively contribute to the environment and minimize negative impact towards our ecosystem. To minimize impact towards climate change, our business is committed to utilizing our natural resources efficiently and effectively. Sustainable and responsible resource allocation and utilization is our main objective through our environmental projects.

To meet this objective, our company’s environmental sustainability commitment encapsulates three main areas: sustainable material sourcing energy efficiency through utilization of various energy-saving technologies, and zero waste management programs.

To meet this objective, our company’s environmental sustainability commitment encapsulates three main areas: sustainable material sourcing energy efficiency through utilization of various energy-saving technologies, and zero waste management programs.

Goal 7 – Affordable and Clean Energy

Target 7.3. To utilize energy efficiently at PT Pan Brothers Tbk and Group

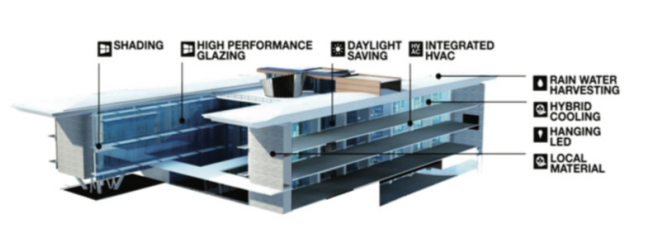

The Company is committed towards minimizing negative impact towards the environment and continuously strives to apply greener building and manufacturing concepts. Our Office Building located in the production complex of Mojosongo Boyolali, Central Java has been awarded the Platinum standard by the Green Building Council of Indonesia based on its 'green building concept'. The company has determined that all new factories, office buildings, and machineries must and will be environmentally friendly in terms of its energy and water usage. We are committed to utilizing at least 30% renewable energy sources across all our 19 entities by 2030.

GREEN OFFICE IN BOYOLALI

Energy Saving Features

Water Conservation Features

Efficiency Statistics

ENERGY CONSUMPTION

Average energy intensity has decreased by 30.25% between 2016-2020

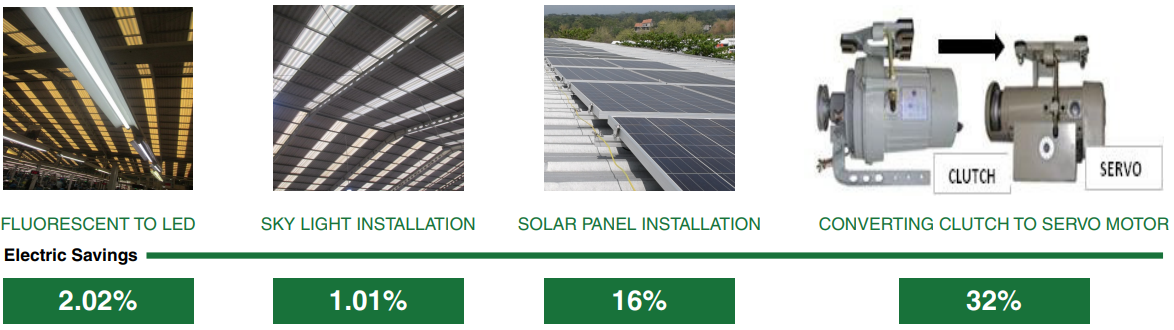

Energy Efficient Technologies

The efficient use of energy and water to support all business activities at all operational facilities is the company's priority program. The company strives to minimize overall carbon footprint and ensures the efficient use of resources to minimize environmental risk. Every business unit of the company is expected to carry out its activities in an energy efficient way without compromising productivity.

WATER CONSUMPTION

On average, intensity of water consumption has decreased by 31.2% between 2016-2020

Rainwater Harvesting (Total Capacity 480m3)

Recognizing Indonesia’s excessive reliance on groundwater, Pan Brothers is committed to harvesting rainwater and utilizing it for our operational activities. We are in the process of installing an auto valve to refill & drain in rain water tank system automatically.

Goal 12 – Responsible Consumption & Production

Target 12.5. To substantially reduce waste production through prevention, reduction, recycling and reuse across all PBRX facilities

Sustainable & Local Material Sourcing

In line with our objective to ensure transparency throughout our supply chain and maintain sustainable resource allocation and utilization, the company is committed to sustainable material procurement and has engaged with global suppliers and buyers to make this initiative a universal commitment.

After conducting a traceability study across all our garment manufacturing facilities on the materials we regularly source to produce garments, the Company has decided to focus on increasing the % of sustainable and recycled/recyclable materials used in production by (1) encouraging buyers and global partners to demand and develop products that are environmentally sustainable and (2) advising and collaborating with global suppliers to produce more sustainable material over the long-run.

To ensure compliance, traceability and transparency in our material sourcing efforts, the Company only classifies materials sourced as ‘sustainable’ or 'recycled' if suppliers have the following certifications:

- Sustainable: PFOA/PFOS Free, Biodegradable, RDS, BCI, GOTS, OCS, OEKO-TEX, IOS MAT 0010, Bluesign, PFC Free, C0, GRS (Global Recycling Standard), RCS (Recycled Claim Standard)

- Recycled: GRS (Global Recycling Standard), RCS (Recycled Claim Standard)

More information about our progress can be found in our sustainability report – broken down by fabric and accessories.

Sustainable Product Development

Through subsidiaries such as PT. Ocean Asia Industry and Continent 8, PBRX has also begun developing sustainable products – using organic fibers and natural dyes for garment products and encouraging buyers around the world to partner with us in this initiative.

Kapok Organic Fibre

Kapok fibre is naturally versatile fibre for textiles, which may be spun into the thinnest yarn counts, and blended to create a wide range of fabrics and insulation materials. Products containing kapok fibres are naturally comfortable, lightweight, hypoallergenic, and soft to the touch. Kapok fibre is a non-food fruit crop which can be picked, like an apple, from the tree on which it grows - leaving the tree to grow and prosper. Kapok trees need no irrigation, no pesticides, and no fertilisers. They can grow on hills, in a biodiverse environment, and on land which is not suitable for agricultural purposes - resulting in 100% positive impact on the environment

Natural Dyes

We are also developing products using natural dyes derived from natural ingredients such as leaves, roots, bark, berries, nuts. The extraction has been done with water and is a 100% environmentally friendly practice as the waste can be used as fertilizer or biofuel.

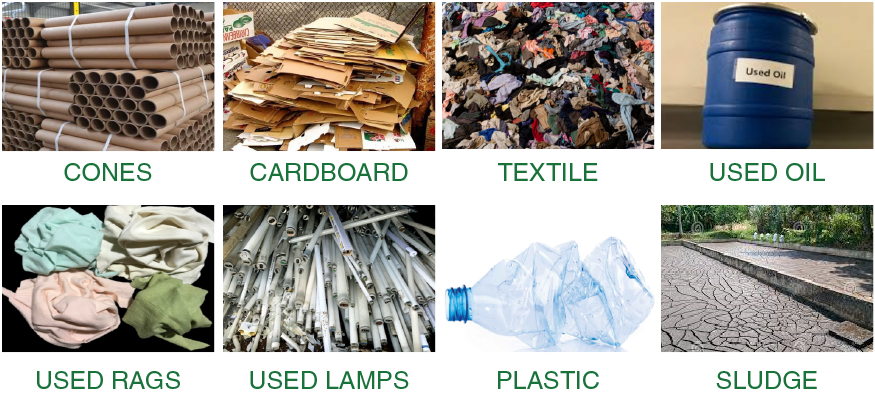

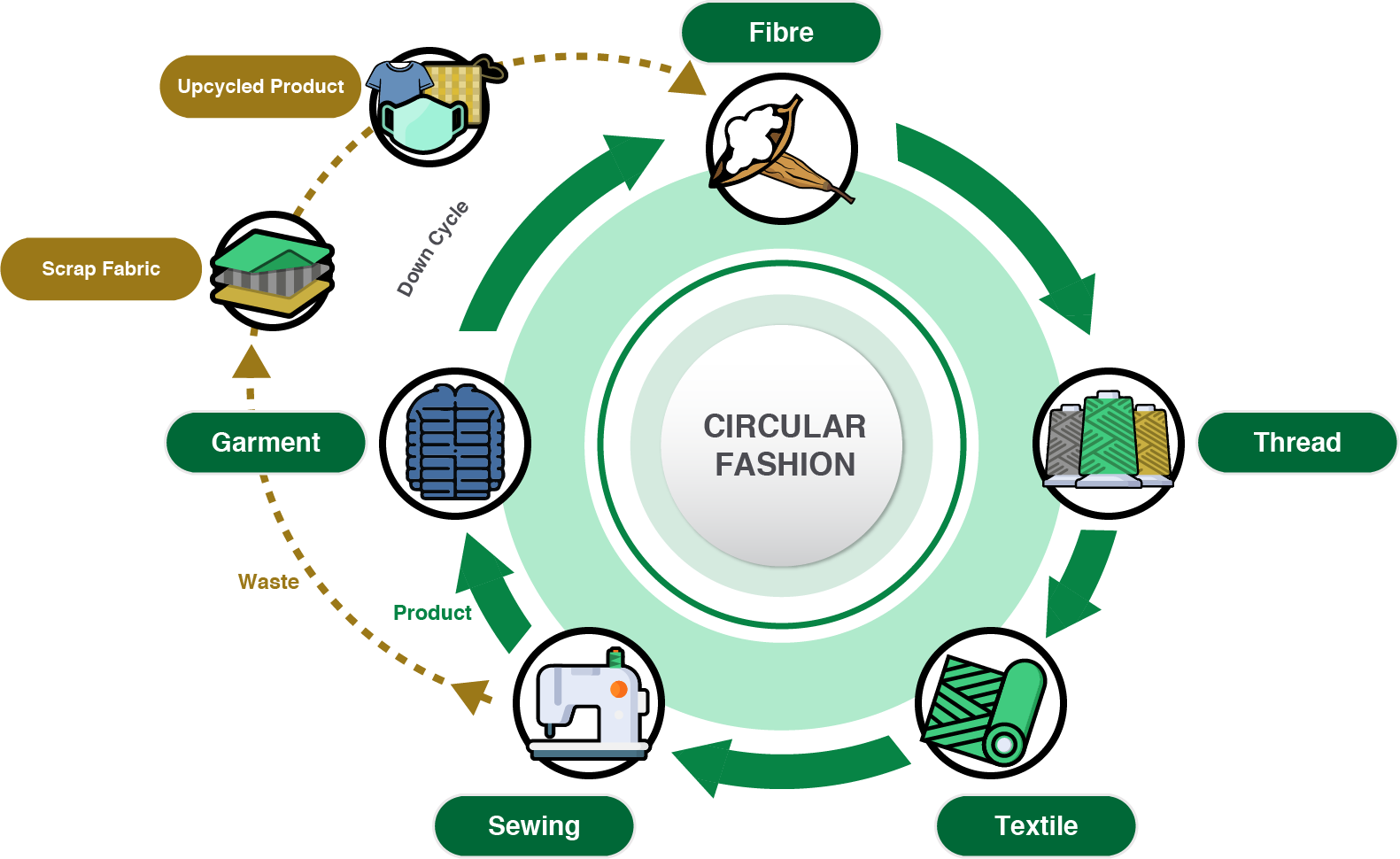

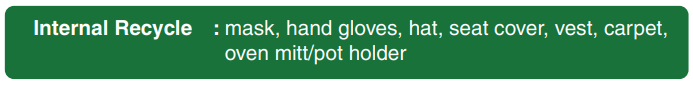

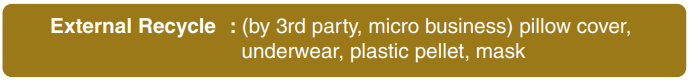

Zero Waste Management Program

Recognizing our tremendous environmental footprint as an integrated garment manufacturing company, we manage our waste as per our commitment to be an environmentally responsible business

8 Types of Waste Generated

% Waste Change (2016-2020)

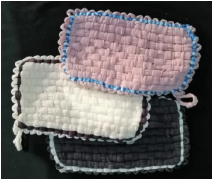

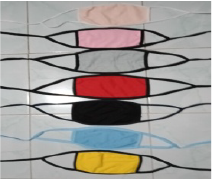

Upcycled Scrap Fabric Projects

We turn trash into treasure through upcycling scrap fabrics generated by our textile and garment production facilities.

SAY NO TO PLASTIC INITIATIVE

To minimize plastic usage across our offices and production facilities, we launched the Say No to Plastic initiative and provided our employees free reusable drinking tumblers to eliminate single use plastic bottles. We plan to expand this initiative to all our production facilities and implement more comprehensive programs to minimize other types of plastic waste generated in 2021

SAY NO TO PLASTIC BOTTLE OFFICE

REUSABLE WATER BOTTLE INITIATIVE

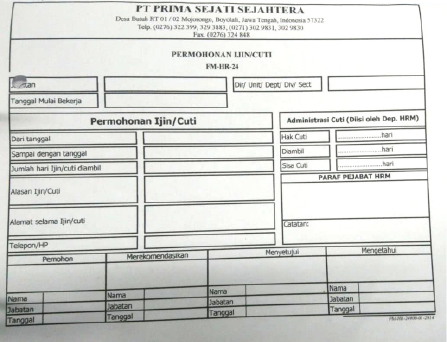

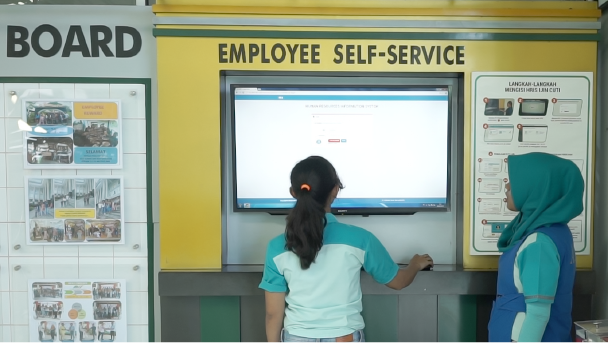

PAPERLESS PROJECT

The company has initiated a paperless project in efforts of becoming more environmentally friendly and improving the efficiency of the work process for several production-related activities. Digitalization of these processes also ensures data accuracy, improves digital literacy of our workers, and enhances the security of our information.

HR Self Service

165,496 sheets of paper reduced from 2016 to 2020

Before

After

Digital Needle Management

54,750 sheets of paper reduced in 2020

Before

After

WASTEWATER TREATMENT